Simple Fieldbus Integration Without Programming Effort

Fieldbus Upgrade for HART Devices

The 4..20 mA current loop with HART interface remains the industry standard for transducers. A fieldbus interface with device integration capability and scriptable configurability offers an inexpensive retrofit for these devices for operation with Foundation Fieldbus and PROFIBUS PA.

It’s now been 25 years since work started on developing fieldbuses for the specific requirements of process automation. Foundation Fieldbus H1 and PROFIBUS PA use a ‘Manchester Bus-Powered’ (MBP) physical layer compliant with IEC61158-2 Type 1. As with the analogue 4..20 mA current loop, this permits a remote feed to the devices and the development of intrinsically safe devices for potentially explosive atmospheres. Although the digital communication protocols include a powerful feature set and offer many advantages in practice, fieldbuses are used in only a small part of production systems. There are many reasons for this lack of acceptance. The control systems use only the process values from digital field devices, and not their diagnostic and parameterization options. Or the ‘control in the field’ models that utilize intelligent field devices are not supported by the control systems. Users therefore see virtually no benefits in using fieldbuses, and also face complex challenges when commissioning, troubleshooting and replacing devices.

In the future, however, Industrie 4.0 and derived concepts such as the NAMUR Open Architecture (NOA) will be focusing on the extensive data that digital field devices can supply for diagnostics and asset management. It is a fact that at least three-quarters of all transducers and positioners being installed today are still equipped with the trusty old 4..20 mA current loop. For this reason, the standard models of field devices typically have an analogue interface, which is usually supplemented with a HART interface for parameter setting. Manufacturer-specific interfaces for parameterization and diagnostics are also often included.

Despite this, new (and often very large-scale) production systems are also designed around fieldbus, which means device makers must ensure they also offer products for this segment. The analogue power interface and HART modem must also be replaced with a digital fieldbus interface. This requires development work for both software and hardware. The budget for a fieldbus integration project can quickly run into a six-digit amount, while the time required to achieve completion is typically between 6 and 12 months. While this kind of effort may be acceptable for major manufacturers, this approach is not attractive to smaller manufacturers who sell only small volumes of fieldbus equipment.

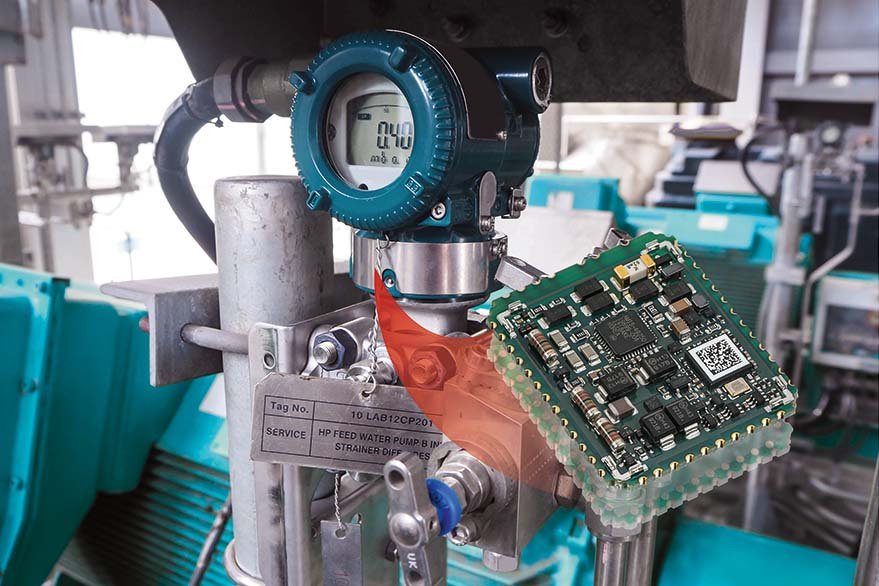

For this customer segment, Softing has developed an integration model consisting of a hardware module and a development tool, which enables the straightforward retrofitting of HART and Modbus devices for Foundation Fieldbus and PROFIBUS PA without any programming. The combination of commModule and commScripter enables the low-effort, cost-effective, and flexible integration of Foundation Fieldbus and PROFIBUS PA into existing field devices and devices still in development.