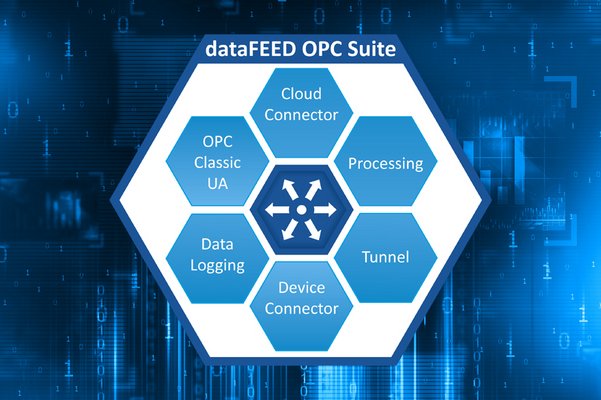

Get To Know dataFEED OPC Suite and Elevate Your Business With Convenient IT/OT Integration

dataFEED OPC Suite enables you to conveniently and easily extract and consolidate your process data for use in modern Industry 4.0 solutions.