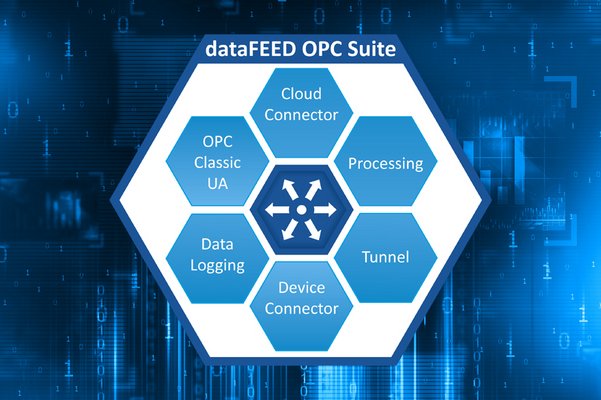

Accelerating Digital Transformation With Easy OPC UA Implementation

In our digital transformation blog post series, we explore the central role of OPC UA for the seamless integration of information technologies (IT) and operational technologies (OT). Let's take a closer look at why OPC UA is important for digital transformation and which key technologies use this powerful standard for seamless data exchange.