My Softing Login

-

Machine Connectivity and Edge Computing

A combination of connectivity and edge computing solves the integration of machine data in IIOT applications in an efficient and scalable way.

- You are here:

- » Industrial

- » Expertise

- » Industrial IoT

- » Edge Computing

Edge Computing

Edge computing describes the decentralized processing of data, managed via a central platform. Edge computing is of great importance for the industrial Internet of Things. In many applications, the amount of data is so large that not all data can be transferred to a central (cloud) platform. Or an application requires short latency times that can only be achieved by processing the data close to the machine.

Container technology has developed into a de facto standard for managing software at the edge level. Docker containers are supported by all major cloud service providers and other industrial edge providers. In addition, other common IT tools such as Kubernetes or Portainer can be used to manage such an environment.

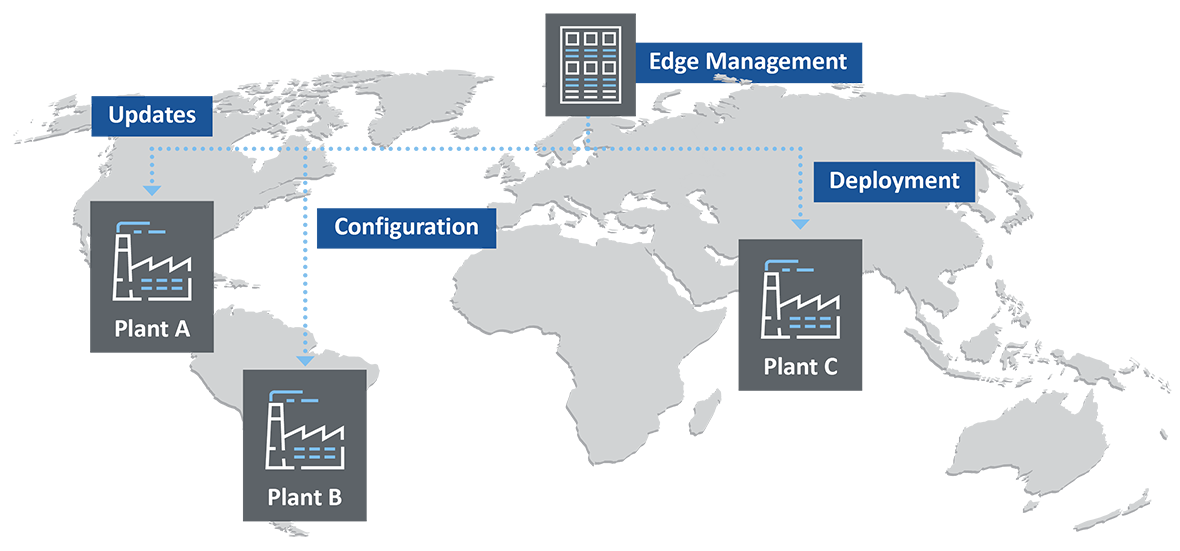

As part of an industrial edge, connectivity can be operated centrally and across locations.

Scalable data integration

Our connectivity products use container technology or standard services for edge computing. This integration of machine connectivity and edge computing in an industrial edge offers considerable advantages:

- Distribution, updates and configuration of connectivity can be efficiently solved centrally and within the framework of comprehensive IIoT operating concepts. Since the products can be easily and flexibly deployed on standard hardware or as part of cluster solutions, specialized hardware is not required in most cases..

- Our products support open standards and standard protocols such as OPC UA, MQTT, and httpREST. This opens up a wide range of options for securely integrating machine and device data into IT applications. This also entails seamless integration into the IIoT reference architectures of large cloud platforms.

- All connectivity products for the industrial edge benefit from our more than 30 years of experience with industrial communication. They combine innovative technology with product maturity and guarantee reliable and safe operation in complex production environments.

All in all, these advantages help the user to make his IIoT solution flexible and scalable and to reduce overall costs over the lifetime of the solution.

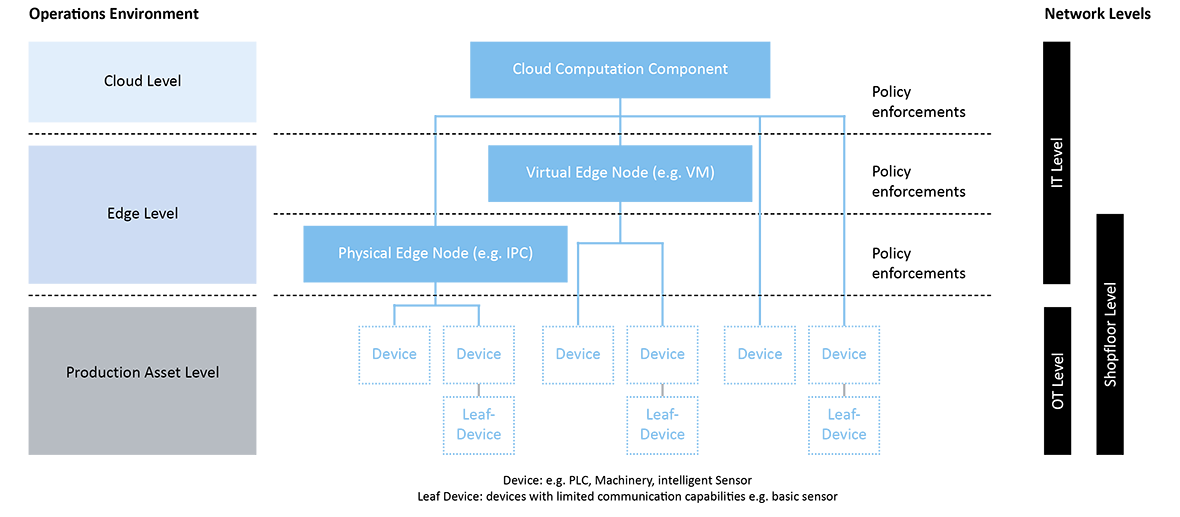

Cloud level, edge level and production asset level as defined by the OMP.

Softing supplies connectivity products that can be used at the edge level.

Softing product families for the industrial edge

The Softing portfolio currently includes the following product families for the industrial edge:

edgeConnector product family:

Access to process and machine data in PLCs and CNC machines, basis for many typical IIoT applications (OEE, predictive maintenance, machine learning, etc.)

smartLink product family:

Access to device data (sensors, actuators) for asset management and asset monitoring applications

edgeAggregator product family:

Server aggregation and additional security for OPC UA-based data integration

edgePlug product family:

Access to process and machine data in PLCs and CNC machines, fully integrated into Siemens Industrial Edge

Downloads

-

Articles & White Papers

- Machine connectivity and industrial edge computing | Technical Articel (Industrial Ethernet Book, 7-2023)

- Software-driven innovations | Technical Articel (Industrial Ethernet Book, 7-2023)

- Benefits and potential of edge computing | Technical Articel (Industrial Ethernet Book, 11-2021)

- Insights Into Connecting Industrial IoT Assets | White Paper, Publication by the Open Manufacturing Platform

- Edge Computing in the Context of Open Manufacturing | White Paper, Publication by the Open Manufacturing Platform