Unlocking CNC Connectivity with Softing edgePlug Software

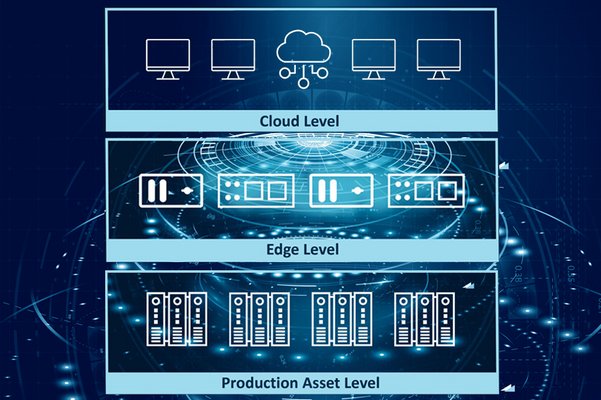

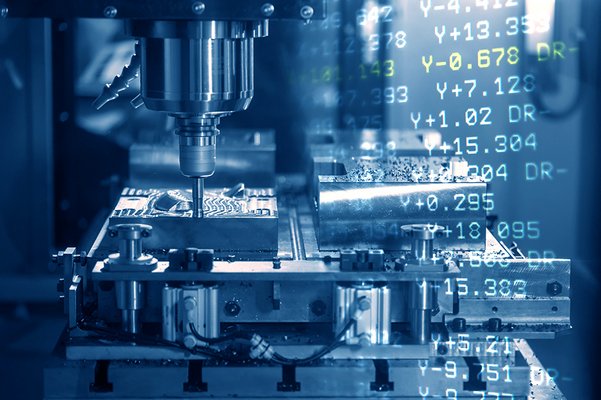

Manufacturers running CNC machines with SINUMERIK 840D controls face the challenge of extracting performance and process data from the shop floor for analysis. This data is essential for optimizing operations via powerful business applications and has been inaccessible until now. The remedy is a versatile software solution that is scalable, cost-effective and easy to use, allowing manufacturers to extract data from their CNC controls while having the freedom to connect to higher-value applications.