Ethernet-APL – Network Topologies

Ethernet-APL (Advanced Physical Layer) is the new standard for the process industry. It is based on the 10BASE-T1L specification as per IEEE 802.3cg and facilitates two-wire Ethernet to the field. The primary advantage of Ethernet-APL is the interoperability and flexibility achieved by the seamless connection of field devices with rapid data transmission on the information layer, in both small networks at short distances as well as in large networks covering long distances. Importantly for the process industry, Ethernet-APL also supports the intrinsically safe ignition protection type “i” in Ex Zones 0, 1, and 2. With the Ethernet-APL technology, the future digitalization of automation networks is relatively easy to implement, assuming several preconditions concerning network topology are considered as part of the equation.

Three Different Variants

Looking at the huge number and diversity of plant types, the various models involved – and above all the size –, the network system should be easy and inexpensive to expand, and should offer redundancy while being able to handle the specific requirements of the process industry, including harsh environments or operation in potentially explosive atmospheres . The Ethernet-APL Engineering Guideline outlines a number of network topologies for Ethernet-APL networks, although the circumstances for the Ethernet-APL spurs are the same for all topologies. Ethernet-APL devices can be connected to a switch by a Category IV cable (no longer than 200 m) and can communicate at a transmission rate of 10 Mbps. Let's take a closer look at three of these variants.

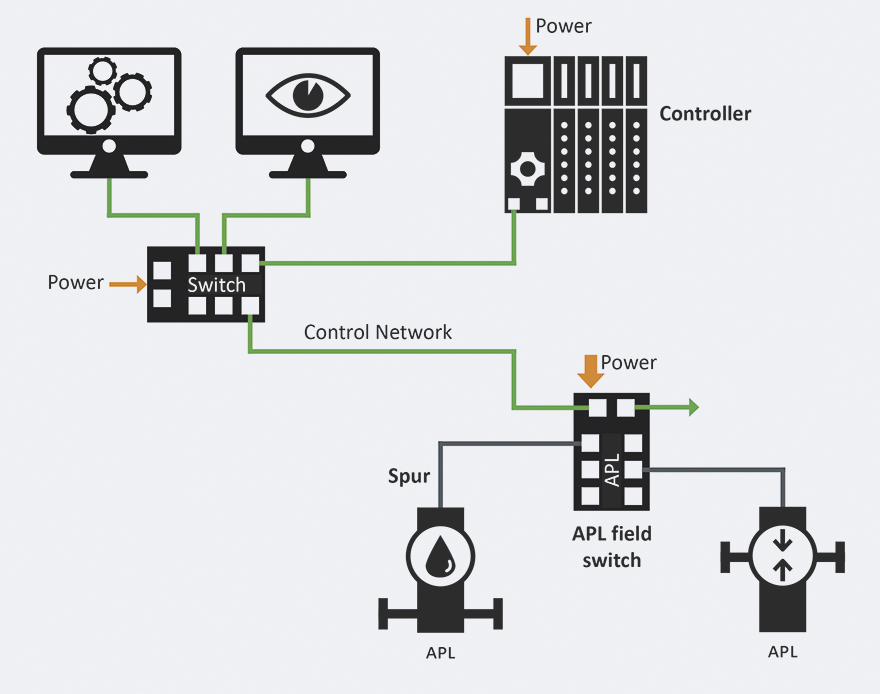

Variant 1: APL field switches are connected directly to a standard Industrial Ethernet network, with the configuration of the installation environment largely determining the location – i.e. whether these are installed in the control cabinet or out in the field. In this version, the APL switch is connected directly to the control network using normal Ethernet copper cables or fiber-optic cables. The typical transmission rate in this section of the network will be 100 Mbps. This is equivalent to today’s Fieldbus structures and is intended to accommodate the brownfield plants that were installed at a time when the rapid pace of digitalization was not yet foreseeable and process control fell far short of today's requirements – but is now being asked to keep step with 21st-century developments.

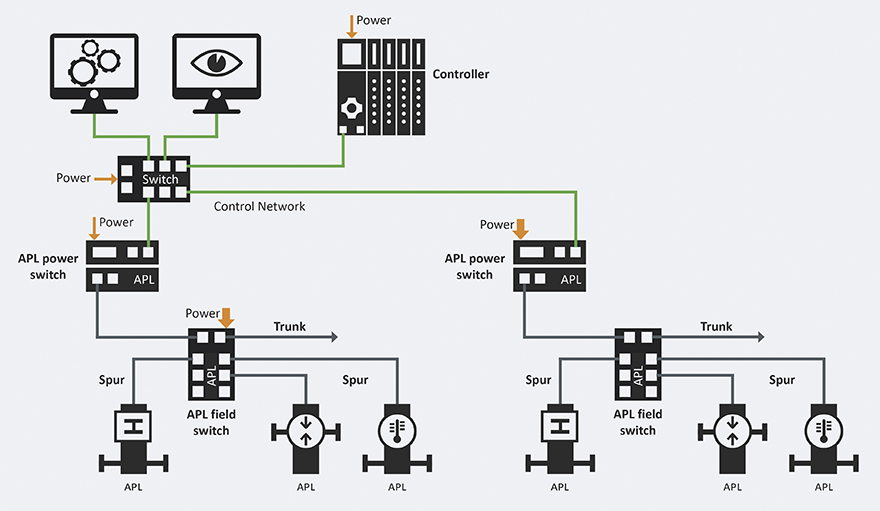

Variants 2 and 3: These variants envisage a network structure that is similar to the one in the first variant but are implemented using trunk technology with conventional APL switches. In this scenario, there are two variants that differ in their choice of deploying an APL power switch with an autonomous energy supply or deploying an APL field switch that needs to be powered with an additional energy source.

In terms of installations in ATEX environments, the 2-WISE explosion protection model (2-Wire Intrinsically Safe Ethernet) should be mentioned at this juncture, which builds on the tried-and-tested FISCO (Fieldbus Intrinsically Safe Concept) model.

Network Stability – Easily the Biggest Headache for Plant Operators

To ensure that a PROFINET network can be operated to be both stable and fail-safe, it is essential to monitor the load that Ethernet-APL devices are exposed to. Continuous control of load peaks works to prevent sporadic outages affecting individual devices due to overloading. This is achieved by limiting the ingress and egress data traffic at switch ports – as also envisaged by the IEEE (Institute of Electrical and Electronics Engineers) – because where networks transition in the switch from 100 Mbps to 10 Mbps, a higher network load in the 100 Mbps control network is especially critical for the Ethernet-APL devices on the 10 Mbps spurs. This 10 Mbps is, after all, only 10% of the data throughput compared with the control network.

Ethernet-APL Switch Takes Care of Net Load Rate Limits

As already mentioned, the net load is a critical factor that needs to be effectively countered. Accordingly, Softing has developed special Ethernet-APL switches that set the respective net load rate limits to ensure stable network operation without overloading, and which support both copper and fiber-optic connections. These are especially suited to the Variant 1 network topology mentioned above and will be available from the second half of 2023. Optimized variants are also planned for installation directly in the field and the control cabinet. The first Ethernet-APL field switch, now available as a prototype, is a version for direct installation in the field and allows the connection of Ethernet-APL field devices that are installed in Ex Zones 1 and 0. To avoid having to install additional gateways during the transition period, the recommendation here is to integrate the PROFINET-PROFIBUS PA proxy into the Ethernet-APL field switch. Softing also has the right solution here, offering versions of its Ethernet-APL field switches with an integrated PROFINET-PROFIBUS PA proxy.