Phoenix Digital Networking Modules Connect Newer Head-End PLCs to Legacy I/O

You have a big project at your plant, and it might seem like the scope is growing every time you turn around. The project goal is to improve plant efficiency, which means you’re replacing some manual processes with automation. One part of the project requires updating the head-end control system. But what about the remote I/O? Will that need to be replaced too? If your new head-end control system can’t communicate with the 20-year-old I/O, it’s also not going to be able to use the old network. Now, you might think you need to replace both the network and remote I/O — and the cycle continues.

Fortunately, to achieve your project goal, you only need to replace the head-end PLC — not the network and not the remote I/O. What you need is an industrial networking solution that lets you install the new head-end control system and still keep your legacy network and legacy I/O.

This is exactly what Softing and Phoenix Digital networking modules can do, and it’s why Softing is a Rockwell Technology Partner, helping Rockwell customers with this challenging scenario.

Imagine the cost to replace a head-end controller and remote I/O, as well as the networking connecting the remote I/O, in a nuclear power plant. Or consider an oil and gas refinery that needs to connect its new ControlLogix® head-end processor to its PLC-5 remote I/O network. These are two example projects in which Softing has eliminated unnecessary scope creep. In the past, they would have required replacing the remote I/O and remote network, along with the head-end PLC.

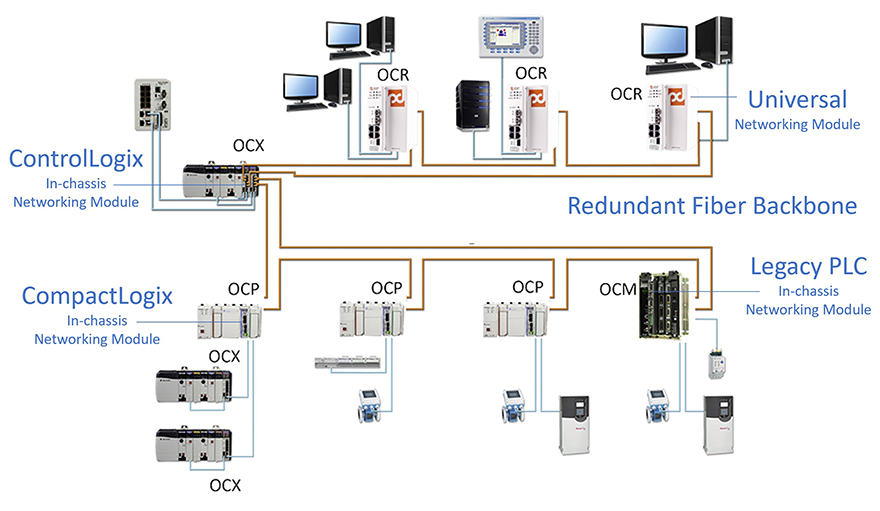

Phoenix Digital addresses these challenges with a built-for-purpose Ethernet networking solution. Its in-chassis communications modules provide a fast, cost-effective way to connect new head-end processors to legacy remote I/O networks, reducing expenses and minimizing the downtime associated with a legacy network upgrade.

For example, let’s say you’re upgrading your old head-end PLC to ControlLogix and in the field, you have several PLC-5s running DataHighway back to your old head-end PLC. Simply install an in-chassis OCX module with your new ControlLogix PLC and install an OCM module with your PLC-5. Both Phoenix Digital modules are now communicating DataHighway between your new head-end PLC and your legacy PLC-5 network across fiber.

Extending the Life of Your Legacy Network

Whether you use Rockwell Automation PLCs — like ControlLogix, CompactLogix, SLC-500 or PLC-5 — or another vendor’s PLC, Phoenix Digital communications modules provide a simple networking solution to connect newer headend PLCs to legacy remote I/O minimizing rip and replace and reducing overall project cost, time and effort. With command line interface coding gone, these modules are easy to integrate, configure and maintain, and they require no software updates. They also let you leverage your existing fiber optic network (such as OM1, OM2, OS1 or OS2) where others can’t and will work well with the following legacy protocols:

- Remote I/O

- ControlNET

- Genius

- Modbus

- DataHighway

- Control Technology, Inc. (CTI) remote I/O

Reusing Your Fiber Cables

In addition to using Phoenix Digital communications modules to connect newer head-end PLCs to legacy networks, these modules offer a drop-in solution once it’s finally time to replace the remote I/O with a newer PLC. Extending the example above, let’s say a few years have gone by since the project ends. You now have a new ControlLogix head-end PLC communicating DataHighway to several PLC-5s across fiber. What happens when one of the remote PLC-5 devices fails and needs upgrading?

This is a tough situation for an IT switch, but for Phoenix Digital, this is exactly the kind of situation the networking modules are designed to solve. Let’s say you want to replace the failed PLC-5 with a CompactLogix unit, creating a mix of ControlLogix, CompactLogix and PLC-5 devices. No problem — simply get a Phoenix Digital OCP in-chassis CompactLogix networking module for your new CompactLogix replacement PLC.

Whereas transporting DataHighway and Ethernet/IP at the same time over fiber would be a challenge for most IT switches, Phoenix Digital switches are built for these types of industrial networking situations.

While this is a common challenge for situations in which a legacy PLC fails and there’s no IT switch that can support your situation, the same challenge also exists for planned, phased upgrades. Again, Phoenix Digital networking modules solve both of these common industrial challenges.

Another major challenge with newer switches is that they use expensive laser-optimized fiber cables like OM3 and OM4. If you have legacy OM1 or OM2 cables installed, switching to a new IT networking switch will require ripping out the old cables to install the new compatible cables, further driving up costs. An IT switch solution can require complex architectures using star topologies and complicated redundant configurations. Phoenix Digital networking modules include redundancy out of the box with no configuration, and the ring topology lends itself to a more elegant solution for spread-out industrial networking requirements.

Phoenix Digital communications modules offer a clean and easy way to reuse your existing fiber cables — whether OM1, OM2, OS1 or OS2 — providing a simple Ethernet solution for network migration projects. In addition to unlocking significant time and cost savings and avoiding unnecessary complexities, the communications modules unlock many benefits:

- Since you can use the communications modules for your new network just as you did for your legacy network, you now have one solution for your entire OT network — no new training required.

- Multiple access points are available with each module, simplifying future installations.

- As you add controls, you don’t need to add modules; you can just plug into one of the four to six ports available on the module.

- Because there’s no need to program, deploy and debug a newly managed Ethernet network, you now have cost-effectiveness built into your OT network.

- There’s no service contract — meaning no extra charge for Phoenix Digital services and technical support.

A great example of using Phoenix Digital communications modules for a migration project is a municipal water district in California that is currently using the modules to extend the life of its network. As the district replaces its SLC-500 PLCs and migrates away from remote I/O within the next few years, it will combine its legacy fiber Ethernet — no rip and replace required — along with Phoenix Digital communications modules to create the new network.

To learn more about how Phoenix Digital communications modules can extend the life of your legacy network, or for assistance on your network migration, please contact us.