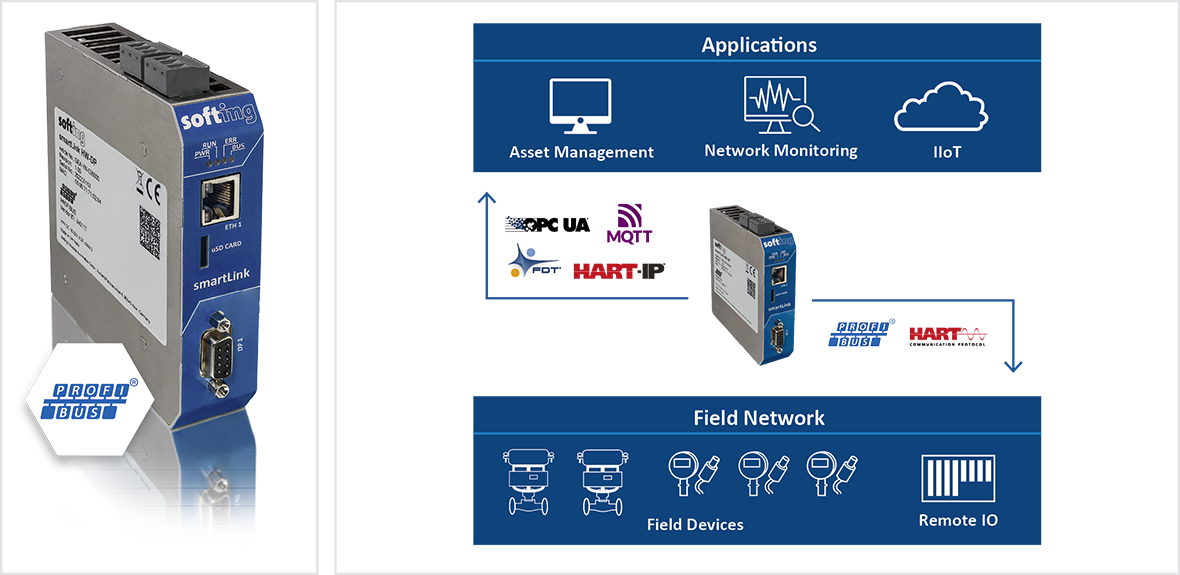

Asset Management Access Point for PROFIBUS DP networks

Connection of PROFIBUS and HART devices to HART IP, OPC UA, MQTT and FDT

smartLink HW-DP provides PLC independent access to PROFIBUS DP Networks. It enables Plant Asset Management for field devices using standard industry tools and allows using HART IP as a standardized format. smartLink HW-DP is a compact tool that can be integrated without interfering with the operation of existing installations. Thus, it enables Industry 4.0 connectivity for new and existing PROFIBUS DP networks.

Overview

Configuration, Parameterization and Plant Asset Management Using Standard Industry Tools

- Independent of configuration tools

- Centralized and time-saving parameterization of PROFIBUS and HART field devices directly from the control room

- Access from Plant Asset Management applications for field devices configuration based on FDT / DTM and EDDL standards (acyclic master)

Ethernet Access Point to PROFIBUS DP

- Provides 2nd channel to access the field devices

- Acts as PROFIBUS DP master class 2

- Support of one PROFIBUS DP segment

Key Component for Transition to State-of-the-Art Technology

- Re-use of existing PROFIBUS segments without requiring modification

- Access to cyclic and acyclic data via HART-IP and OPC UA

Asset Management and Parameterization of HART Devices

Configuration, Parameterization, Plant Asset Management

- Secure, standardized access to devices

- Parallel to and independent of the controller

Inexpensive and low-risk integration

- Connection of a large number of HART devices without rewiring the devices

- Use of existing infrastructure using „HART over PROFIBUS“

- Large number of supported Remote IOs

Compatible with established standard applications

- Uses HART-IP as standard application protocol

- Proven and tested with Emerson AMS Device Manager, ABB FIM, E+H FieldCare and PACTware

Asset Management and Parameterization of PROFIBUS Devices

Configuration, Parameterization, Plant Asset Management

- Secure, standardized access to devices

- Parallel to and independent of the controller

Compatible with established standard applications

- Drivers available for FDT

- Proven and tested with E+H FieldCare and PACTware

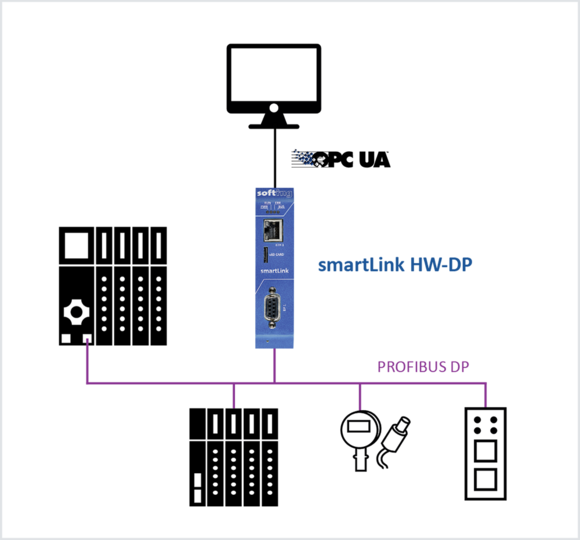

Direct Access to Process Data from PROFIBUS Networks

Capturing process data directly from the network

- Live provision of all process data for further use in typical Industry 4.0 applications such as data analytics

- Collecting data directly from the network, replacing the need to access the controller

- No intervention in the running process

Secure provision of data using OPC UA

- State-of-the-art transmission method in industrial networks

- Fast update cycles over OPC UA possible

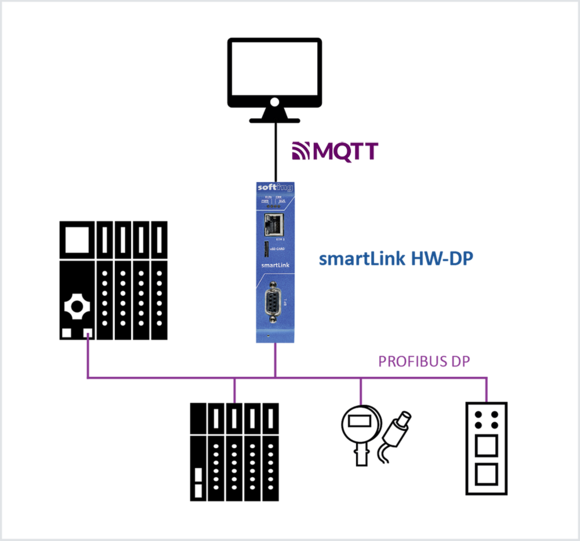

Asset Monitoring and Diagnostics in PROFIBUS Networks

Complete inventory of the entire network

- I&M data from all connected devices

- Automated live queries without configuration

Secure provision of data using MQTT

- State-of-the-art transmission method for cloud connectivity

- Information model based on OPC UA Companion Specifications for PROFINET

Health monitoring of all connected devices

- Diagnostic messages and status of all bus stations

- Statistics parameters for the entire network

Integrated with Softing plantPerfect Monitor application

- Use the plantPerfect Monitor application to monitor the network with all its devices

Technical Data

| smartLink HW-DP | ||

| Hardware | Processor | Intel Cyclone V SoC with dual-core ARM Cortex-A9 |

| Status LEDs (Gateway) | PWR, RUN, ERR, BUS | |

| Real-Time Clock | Real-Time clock with buffering, setting the time via browser or by NTP server (buffer time depends on conditions such as ambient temperature and duration of use) | |

| Interfaces | Ethernet | 1 x IEEE802.3 10BASE-T/100BASE-TX/1000BASE-T, Connector: RJ45 |

| PROFIBUS DP | 1 x Segment with RS485 Physical Layer, Connector: 9-pin Sub-D socket | |

| Supported | Communication Protocols | HART-IP, MQTT, OPC UA, PROFIBUS DP |

| PROFIBUS Remote IOs | Siemens: ET 200SP: 155-6BU01-0CN0 ET 200iSP: 152-1AA00-0AB0 ET 200M: 153-2BA10-0XB0 ABB: S800: CI801, CI840, CI840A S900: CI920N, CI920S Pepperl+Fuchs: LB: LB8105, LB8106, LB8109 FB: FB8206, FB8209 R.Stahl: iS1+: CPM 9440/15-01-11 Turck: BL20: BL20-E-GW-DP, BL20-GW-DPV1 excom: GDP 1,5 WAGO: I/O System 750: 750-333, 750-833 | |

| HART IO Modules | Siemens: ET 200SP: 134-6TD00-0CA1, 135-6TD00-0CA1 ET 200iSP: 134-7TD00-0AB0, 135-7TD00-0AB0, 134-7TD50-0AB0, 138-7FA00-0AB0 ET 200M: 332-8TF01-0AB0, 331-7TF00-0AB0, 331-7TF01-0AB0, 331-7TB00-0AB0, 332-8TF00-0AB0 ABB: S800: AI815, AO815, AI845, AO845A, AI895, AO895 S900: AI930N, AO930N Pepperl+Fuchs: LB: LB3002, LB3102, LB3103, LB3105, LB4002, LB4005, LB4102, LB4105, LB3005A2, LB3006A, LB3106A, LB4106A, LB7104A FB: FB3202B1, FB3202B2, FB3205B2, FB3205B3, FB3302B2, FB3305B2, FB4202B2, FB4202B3, FB4205B2, FB4205B3, FB4205C2, FB4302B2, FB7204B3, FB7304B3 R.Stahl: iS1+: AIM 9461/12-08-11, AOM 9466/12-08-11, AUM 9468/32-08-11 Turck: BL20: BL20-2AIH-I, BL20-2AOH-I excom: AIH40Ex, AOH40Ex WAGO: I/O System 750: 750-484, 75x-842 | |

| HART-IP Applications | Emerson AMS Device Manager V14.1.1, V14.5 Endress + Hauser Netilion (FieldEdge SGC500) ABB FIM V3.01 | |

| FDT Applications | PACTware, Endress + Hauser FieldCare | |

| Physical Properties | Dimensions (H x W x D) | 120 mm x 28 mm x 110 mm |

| Weight | Approx. 430g | |

| Power Supply | 18 VDC ... 32 VDC; SELV/PELV power supply mandatory Typical input current: 200 mA, maximum input current: 1 A (allowing for in-rush current at switch-on) | |

| Typical Power Loss | 5 W | |

| Operating Temperature | -40 °C ... +65 °C (see detailed mounting description in user manual) | |

| Storage Temperature | -40 °C ... +85 °C | |

| Relative Humidity | 10 % ... 95 %, non-condensing | |

| Cooling | Convection, no fan | |

| Mounting | DIN rail 35 mm | |

| Protection Class | IP20 | |

| Conformity / Standards | CE | Electromagnetic compatibility (EMC) and Restriction of Hazardous Substances (RoHS) EN 61000-6-2 Generic standards - Immunity standard for industrial environments EN 61000-6-4 Generic standards - Emission standard for industrial environments EN 55032 Electromagnetic compatibility of multimedia equipment - Emission Requirements Class A EN 55011 Industrial, scientific and medical equipment - Radio-frequency disturbance characteristics – Limits and methods of measurement Class A EN IEC 63000:2018 RoHS, Assessment to the restriction of hazardous substances |

| FCC | FCC 47 CFR Part 15B Section 15.109 (Class A) | |

| VCCI | VCCI Voluntary Control Council for Interferences by Information Technology Equipment, April 2015 | |

Order Information

| Scope of Delivery | |

| Hardware | smartLink HW-DP |

| Documentation | On Website |

| Order Numbers | |

| GEA-YN-026000 | smartLink HW-DP |

| GEA-YN-026001 | smartLink HW-DP 50, Hardware preloaded with licenses for 50 devices |

| GEA-YN-026002 | smartLink HW-DP 100, Hardware preloaded with licenses for 100 devices |

| GEA-YN-026003 | smartLink HW-DP 250, Hardware preloaded with licenses for 250 devices |

| GEA-YN-026004 | smartLink HW-DP 375, Hardware preloaded with licenses for 375 devices |

| LRA-NN-027004 | smartPlus DP, License access to one field device |

| Additional Products and Services | |

| DBA-KM-020410 | mobiLink – Mobile HART interface |

| LRL-TG-020000 | plantPerfect Monitor, perpetual licence including 1 year software updates for 1 device |

| LMA-TG-020000 | plantPerfect Monitor, 1 year software updates for 1 device |

| LAA-TG-020000 | plantPerfect Monitor, 1 year rental licence for 1 device |

Videos

Integrate smartLink HW-DP with FieldCare to access HART field devices

In this tutorial, learn how to integrate and use the smartLink Hardware-DP solution into FieldCare Asset Manager tool from Endress & Hauser to retrieve HART information of field devices connected to HART compatible PROFIBUS DP Remote I/Os.

Integrate and use the Softing smartLink Hardware DP solution in AMS Device Manager

In this tutorial, you will see how to integrate and use the smartLink HW-DP solution into AMS Device manager and access PROFIBUS DP or HART information of field devices connected to HART compatible PROFIBUS DP Remote I/Os.

Downloads

-

Drivers & Software

- smartLink HW-DP | Firmware V1.30

- smartLink HW-DP | Download Checksums V1.30

- smartLink DTM | Firmware V1.10

- smartLink DTM | Download Checksums V1.10

- PROFIdtm V2.24 | for usage in FDT frame applications

- Search and Configure Discovery Tool V2.00

- PDM libraries - for integration into Siemens PDM

- Universal PROFIBUS Driver V5.47.4

-

Manuals & Documentation

- smartLink HW-DP | User Guide

- smartLink HW-DP | Release Notes V1.30

- smartLink DTM | User Guide

- smartLink DTM | Release Notes V1.10

- Training – Initial Setup

- Training – PROFIBUS Configuration

- Training – Troubleshooting

- How to set suitable PROFIBUS Parameters in smartLink HW-DP

- How to choose the right DTM for smartLink HW-DP

- How to use smartLink HW-DP with PDM

- How to create a Profibus Capture with SmartLink HW DP

-

Data Sheets & Brochures