Plant Asset Management in the Process Industry

Connectivity solutions from Softing and Emerson help customers improve plant productivity and increase lifecycles

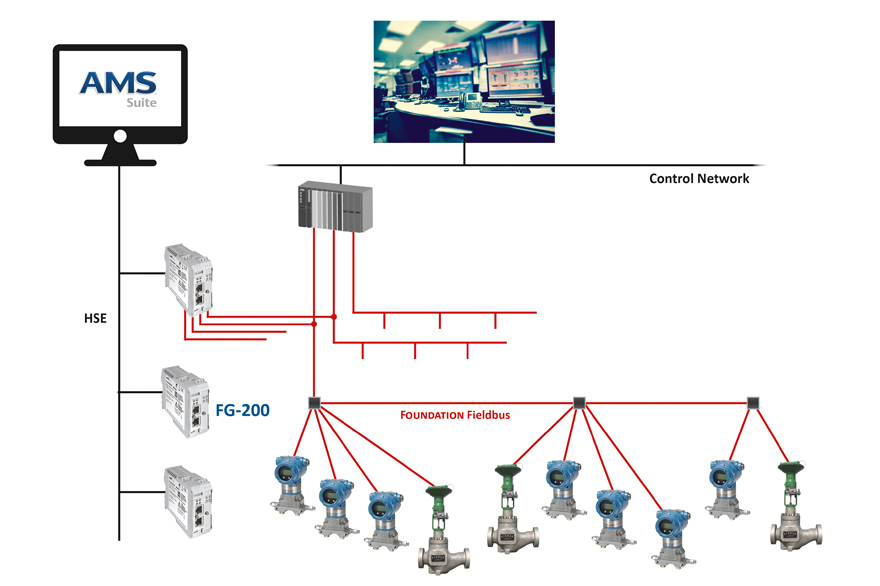

Field devices in modern plants in the process industry can give operators detailed information about the condition of the plant. The collected data helps in planning preventive maintenance work and in optimizing production processes. To transmit data beyond the pure process value and integrate it into higher-level systems, many plant operators use the DeltaV and Ovation control systems from the US company Emerson. In addition, these customers use Emerson's AMS Device Manager (Asset Management Software Device Manager) for commissioning, diagnostics and troubleshooting of field devices connected to Emerson process automation systems. In this way, they are achieving state-of-the-art plant asset management that addresses the increasing demands for energy efficiency and flexibility in modern process production.

What about installations that use third-party controllers?

A growing number of customers want to leverage the unique asset management capabilities of AMS Device Manager in applications with third-party components such as remote IOs or controllers from Schneider Electric, Siemens, ABB or Rockwell. To make this possible, Softing has developed a solution for integrating its FG-200 gateway with AMS Device Manager. The FG-200 gateway was particularly well suited because it supports device redundancy and use in hazardous areas and enables the connection of up to four Foundation Fieldbus H1 links in control and plant asset management systems with Modbus support. This development was carried out within the framework of Softing's membership in Emerson's DeltaV Alliance Product Program.

The gateway allows smooth data exchange

Via the FG-200 gateway, AMS Device Manager directly accesses the process data of Foundation Fieldbus field devices connected to third-party control systems. In addition, the gateway enables remote access to intelligent field devices by enterprise experts worldwide. This ensures end-to-end, horizontal, and vertical networking and smooth data exchange without loss of information. Plant operators can make predictions based on reliable diagnostic functionalities, prevent any failures in time and operate a solid, efficient, and future-proof plant asset management.

Confirmation of the growing demand for such a setup comes from Bo Monta, Sr. Service Engineer - Reliability Solutions, Middle East & Africa at Emerson Automation Solutions: “We are seeing great potential in this type of installation as companies are now becoming more aware that well-structured asset management would mean a better plant in terms of reliability, efficiency and operational effectiveness.”

Do you need more information?

More information about our Emerson connectivity solutions is available here.

Do you have any questions about this topic? We will be glad to help you. Get in touch with us!