Effective Plant Asset Management

Softing joins Emerson’s DeltaV Alliance Product Program and extends intelligent device management across the field to islands of devices and out to the enterprise to remote subject matter experts.

To meet the increasing requirements for energy efficiency and flexibility in modern process manufacturing, information about processes and plant statuses is required which can be exchanged across systems. Emerson, the US based global technology and engineering corporation, helps customers in process and hybrid industries as well as discrete manufacturing to transmit data beyond the pure process value and integrate it into higher-level systems. Many customers around the globe utilize Emerson’s DeltaV and Ovation control systems for process automation. In addition, these customers use Emerson’s AMS (Asset Management Software) Device Manager to troubleshoot, diagnose, and commission the field devices connected to Emerson process automation systems.

Device management for previously unreachable devices

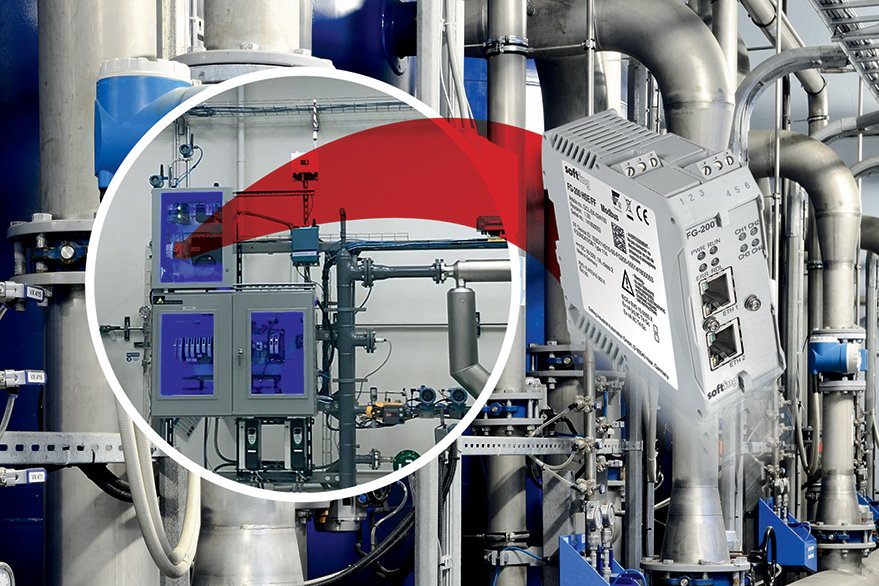

AMS Device Manager together with DeltaV and Ovation is a powerful combination for managing intelligent valves and transmitters and helps to decrease maintenance costs and increase reliability. Since not all critical and essential smart field devices are connected to DeltaV and Ovation, AMS Device Manager requires another type of solution to reach stranded field devices. Emerson saw the need to connect AMS Device Manager to those stranded field devices and recognized hat the Softing FG-200 gateway could talk to FOUNDATION Fieldbus H1 devices. Softing joined Emerson’s DeltaV Alliance Product Program and collaborated with Emerson on the integration of FG-200 and AMS Device Manager. Softing's FG-200 gateway now enables AMS Device Manager to reach those stranded field devices so users are no longer limited to managing only devices connected through DeltaV and Ovation. The gateway provides the added capability of enabling remote management of intelligent field devices by enterprise experts that might be anywhere in the world. This ensures consistent, horizontal and vertical data flow and smooth data exchange without information loss, so that predictions can be made on the basis of reliable diagnostic parameters in order to counteract possible failures in good time and to be able to operate a solid, efficient and future-proof plant asset management system.

Want to delve deeper into the topic? Click here to read the full story.

To learn more about Softing and Emerson Connectivity Solutions click here.