Unlocking CNC Connectivity with Softing edgePlug Software

Manufacturers running CNC machines with SINUMERIK 840D controllers are challenged with extracting performance and process data from the shop floor for analysis. This data is essential for optimizing operations via powerful business applications and has traditionally been inaccessible. Manufacturers will implement custom code for data access, but this solution is costly, time-consuming, and blocks connectivity to high-level, third-party business applications that offer substantial process optimization benefits, like those found in the Siemens Industrial Edge Marketplace.

The Siemens Industrial Edge consists of edge devices, applications and device management infrastructure solutions that can booster operational performance. But without easy access to these powerful resources, accessing CNC machine data and then analyzing it to create actionable insights is a challenge. How do you get the information off the machines and get it where it needs to go?

Delivering CNC Data to the Siemens Industrial Edge

Rising to the challenge, the Softing edgePlug SINUMERIK CNC software provides easy, direct access to SINUMERIK 840D CNC controllers and – as part of the Siemens Industrial Edge ecosystem – delivers information seamlessly to on-premise, edge- or cloud-based applications. These capabilities offer a simple pathway for improving automated CNC operations. By broadening CNC connectivity beyond the narrow reach of legacy solutions, operators now have the ability to make tangible improvements to CNC processes with extracted, analyzed data.

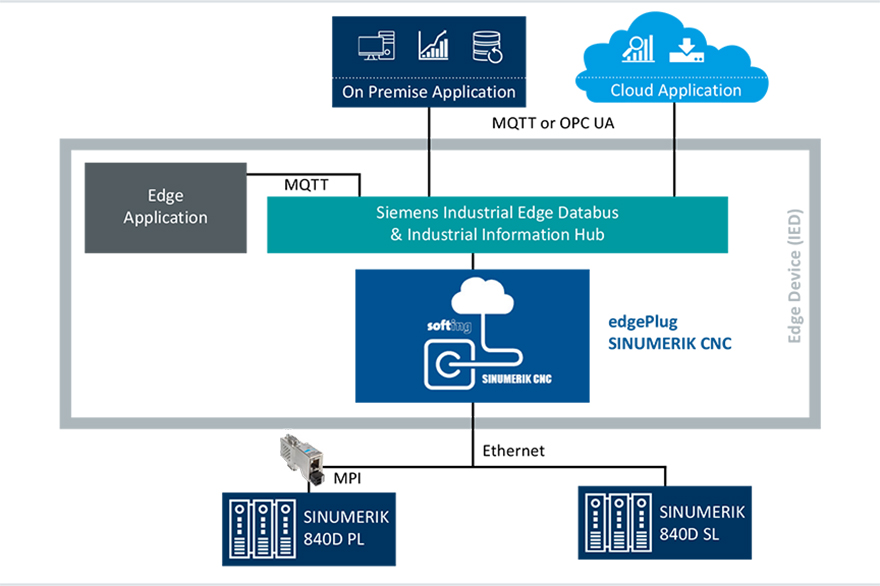

The edgePlug SINUMERIK CNC software connects to CNC controllers via Ethernet to extract data, which then passes to the Siemens Industrial Edge Databus and Industrial Information Hub (IIH) and your preferred application. This is an easy solution to deliver relevant process data to an edge application via MQTT, or to on-premise or cloud applications via MQTT or OPC UA.

The edgePlug SINUMERIK CNC software accesses a broad, diverse array of machine data from Siemens 840D CNC controllers, along with production data like drive current, axis positioning and tool data. The edgePlug is easy to configure, allowing you to manage the software centrally from the Siemens IIH.

Automated, Feedback-based Process Adjustments

CNC operators rarely adjust their machines once in operation due to the risk of causing a breakdown or negatively impacting processes. This high-stakes decision prevents machine control adjustments and restricts beneficial process engagements. EdgePlug’s connectivity delivers improved automation practices, allowing for closed-loop control systems and an easy, repeatable, and accurate way of optimizing operations with feedback data.

Quick edgePlug SINUMERIK CNC Facts

- Access to both the Solution Line (SL) and Power Line (PL) controllers

- One edgePlug instance connects to up to 20 SINUMERIK CNCs

- Automatic tooling recognition

- Setup in less than ten minutes

- Doesn’t require CNC program changes or data point configuration.

This versatile software is a scalable, cost-effective, and simple solution that enables manufacturers to extract data from their CNCs, all while providing the freedom to connect to higher-level applications.

Learn more about edgePlug here.