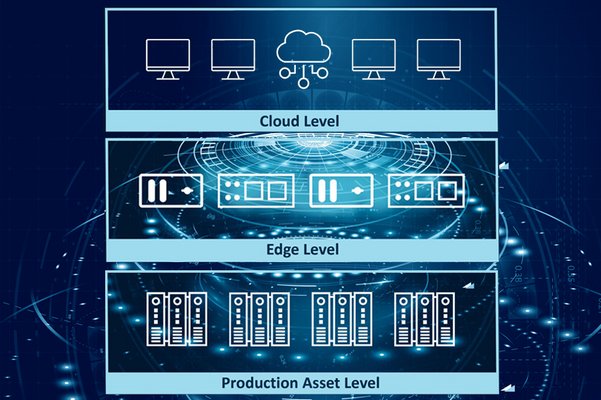

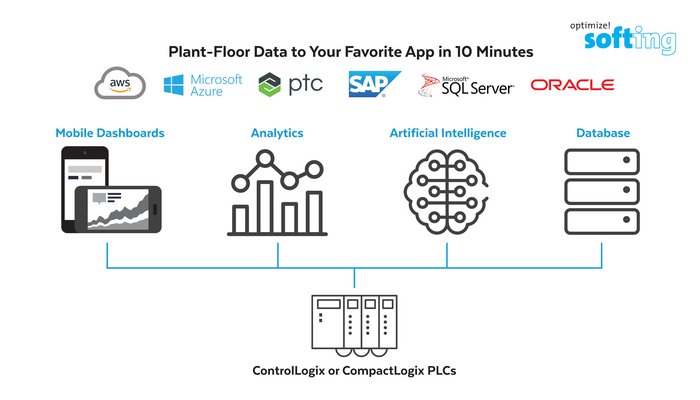

When it comes to starting, operating and expanding Industrial Internet of Things (IIoT) solutions, information technology (IT) architectures play a key role. For example, leveraging IT tools like innovative algorithms can help you increase your production efficiency. At the same time, you may be facing some architecture-related challenges, such as plant- and enterprise-wide deployment migrations, cloud connectivity, database integration, programmable logic controller (PLC) connectivity, security and ongoing maintenance.

While these challenges are typical, until recently it was impossible to build a future-proof, enterprise-wide IT architecture that makes ongoing maintenance possible. PLCs can take decades to upgrade, while the pace at which IT architectures change is dizzying by comparison.