New options with container applications

Clever data management

Resource-saving and universally deployable applications on heterogeneous computing platforms offer new worlds for Industry 4.0 in terms of industrial data. Container applications, which are small software modules providing a narrowly defined functionality, are one example of clever data management in the automation world. Softing has launched a new product family that uses container technology for Siemens and Modbus controllers.

The idea behind it

As mentioned earlier, container applications are software modules with a precisely defined functionality that allow new deployment options delivering numerous benefits for automation technology. Benefits are the low-resource, universal application running on different computer platforms or the practical isolation, encapsulation and portability of software. What makes this approach so special is that containers operate like a kind of virtual machine that contains all the required components. This means that they can run independently of any external components and the existing environment. If several container applications are used on one hardware platform, they share the operating system and, if necessary, certain hardware resources, while being completely separate from each other and from the system as such. This ensures that a container application always behaves identically, regardless of the environment in which it is executed.

Once downloaded, container applications can be deployed within seconds using a single command line and at production level offer the advantage of enabling easy central administration. This can be done either on-premise using a device management system (DMS) or in a cloud setting (e.g Microsoft Azure IoT Edge, AWS IoT Greengrass), and as machine workloads change, the workload can be distributed across multiple container applications.

Smart solution based on state-of-the-art security and know-how

It is important to note that compliance with appropriate security standards outside the container is essential. If multiple container applications are deployed in parallel on one computer, any hacker attacks targeting just one container application will also affect the other containers, since they share the same operating system. And it goes without saying that know-how must be developed for this new technology. Softing has exactly this know-how and offers smart and secure container applications including the latest security methods.

The edgeConnector product family is ready to go

Developed by Softing Industrial, the new edgeConnector family of container applications enables customers to integrate their production into a comprehensive Industry 4.0 environment. After installing Docker Environment for use on Windows, Linux or Mac computers, they are up and running very quickly:

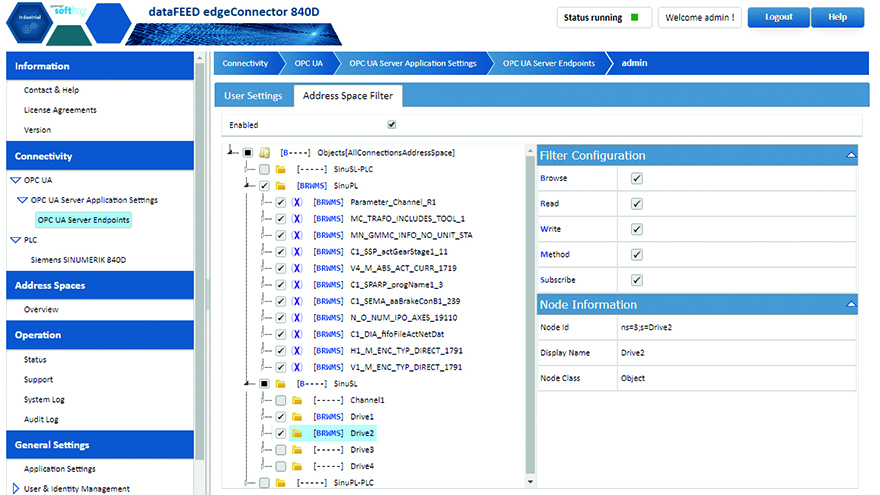

The individual products each access the data of the controllers from different manufacturers via Ethernet or proprietary PLC protocols, using OPC UA (Open Platform Communications Unified Architecture) and MQTT (Message Queuing Telemetry Transport) as the main communication protocols for data transfer and integration. Security is a key priority of the edgeConnector product family. It supports all common encryption and security mechanisms, including role-based access rights and certificate exchange. Configuration, control and administration are carried out locally using an integrated Internet interface or remotely via a REST API (Representational State Transfer – Application Programming Interface), which enables information stored on different systems to be shared.

The edgeConnector family currently includes three products enabling the integration of Siemens and Modbus controllers.

- edgeConnector Siemens supports access to Siemens SIMATIC S7-300/400 and SIMATIC S7-1200/1500 controllers for production data acquisition, manufacturing parameter analysis and predictive maintenance.

- edgeConnector 840D for the SINUMERIK 840D Solution Line and Power Line CNC controllers to read process parameters from the NC area (axis, tool and program data, etc.) the PLC area (status, program sections, alarms) and from drive data (torques, currents, rpm).

- edgeConnector Modbus for accessing Modbus TCP controllers, e.g. from Schneider Electric, Wago, Beckhoff or Phoenix Contact. The product is also able to collect energy data or other process variables from simple Modbus compatible sensors. With OPC UA or MQTT, the data can be integrated then into higher-level management systems such as ERP, MES or is used for process visualization or machine data acquisition.

Customers opting for Softing’s edgeConnector products can choose between a conventional hardware gateway, middleware or a Docker container application when implementing their Industry 4.0 and IIoT (Industrial Internet of Things) applications. Going forward, Softing plans to expand the edgeConnector product family further to enable also Ethernet/IP connectivity for Rockwell and Omron controllers. Softing is also working on expanding configuration options from the cloud.

The complete documentation and downloads for the respective products is available here.