HART-IP in the process industry

Right on track for the IIoT

Asset management remains the key issue determining efficiency and reliability in the process industry. As field devices must be fail-safe, configuring, monitoring and maintaining them proactively is a priority. Digitalization is increasingly gaining inroads into these company processes, making digital communication protocols that meet the requirements of the process industry indispensable. It is becoming apparent that HART and HART-IP are right on track to meet these industry requirements.

HART pushes the adoption of IIoT in process plants

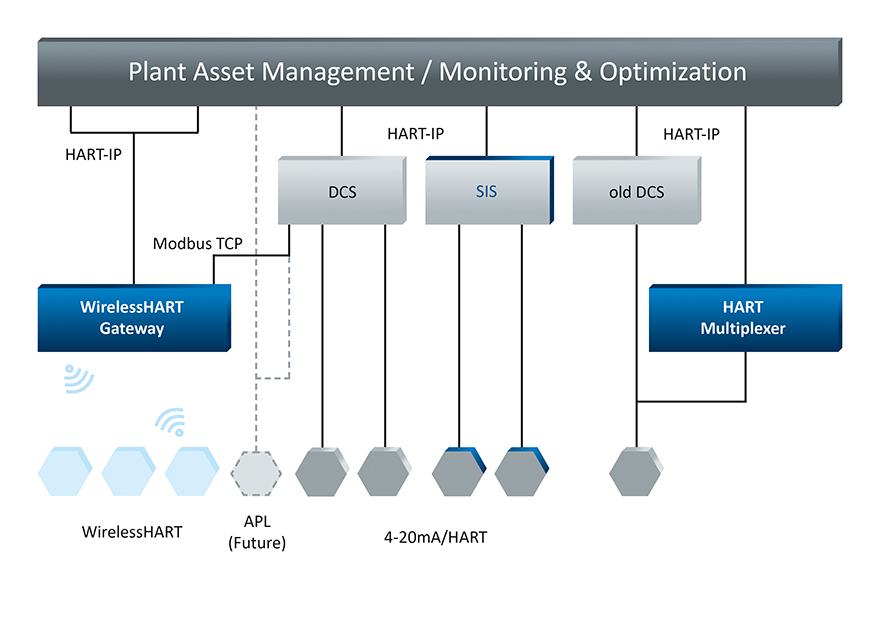

When it comes to digital asset optimization, HART (Highway Addressable Remote Transducer), a bidirectional communication protocol for data exchange between intelligent field devices and software applications (host) is becoming an established option by providing two simultaneous communication channels – one analog and one digital. At the same time, WirelessHART became the leading wireless protocol for process applications, having now been joined by the new HART-IP standard protocol. Specified back in 2012 by the FieldComm Group, HART-IP enables simple vertical data integration from field devices to the control room. The HART protocol can be run over Ethernet, Wi-Fi, or other network media without sacrificing the detailed device setup or diagnostics information offered by existing networks. In addition to providing access to a device’s process variables, the protocol also supports device configuration and advanced diagnostics. HART-IP is therefore set to play an important role in enabling the Industrial Internet of Things in process plants.

HART-IP enables efficient communication between devices

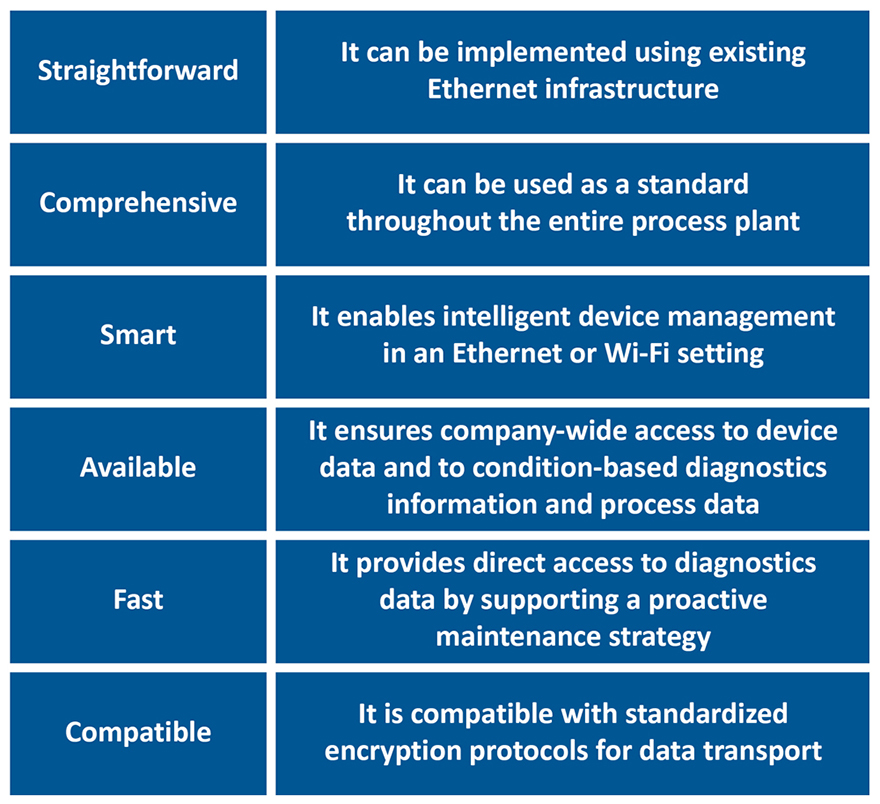

As diagnostic data are highly relevant amid progressing digital transformation, HART-IP becomes more and more of a focus issue for plant operators. This is because the previous data collection of dynamic variables on status information such as temperature, vibration or acceleration via Modbus registers or OPC groups is both time-consuming and error-prone. In contrast, intelligent HART devices support centralized configuration as well as diagnostic and status monitoring. HART-IP enables the integration of complete plant-wide, large-scale solutions and offers a high degree of interoperability between devices and applications. The protocol runs over IP-based networks such as Ethernet and Wi-Fi and works over UDP (User Datagram Protocol) and TCP (Transmission Control Protocol) with IPv4 or IPv6 (Internet Protocol Version 4 or 6). HART-IP is a high-level application protocol independent of the underlying media and works over standard Ethernet (IEEE 802.3), both copper and fiber, as well as Wi-Fi (IEEE 802.11). It is therefore suitable for use with standard infrastructure components like LAN switches, routers, access points, cables and connectors, and also supports a variety of speeds such as 10 Mbit/s, 100 Mbit/s and 1 Gbit/s.

Security First

HART-IP is expected to be predominantly used within the plant perimeter. However, if the protocol is to be deployed beyond the plant perimeter or via the Internet or Wi-Fi, specific security measures must be implemented (such as firewalls, VPN tunneling, Secure Socket Layer (SSL), and remote authentication). The standard encryption protocols will continue to evolve and HART-IP is designed to be adaptable to new versions. NAMUR Open Architecture (NOA) will be yet another driver boosting the use of HART-IP. Although the structure of the classic automation pyramid offers a high level of operational reliability, it lacks the flexibility required for the implementation of new technologies in connection with Industrie 4.0 solutions. This is why NAMUR added an open OPC UA interface, creating the possibility of transferring data securely from the automation world to the system world for monitoring and optimization purposes. Here, too, HART-IP is available as another open interface.

More than anything, HART-IP is:

HART-IP support from Softing

Serving as a patented backhaul network for wireless HART gateways and HART infrastructure components, HART-IP will facilitate and, above all, simplify the transfer of data and information in process plants. This would create the fundamental prerequisite for the successful implementation of Industrie 4.0 applications.

Softing supports HART-IP technology, and with its smartLink HW-DP product it offers an NOA-compliant gateway that collects data from HART devices via PROFIBUS remote I/Os and makes it available via OPC UA in accordance with Companion Specifications. Moreover, a HART-IP server integrated into smartLink HW-DP provides transparent access to HART field devices via Ethernet. This will make it possible to use any HART-IP client, such as Emerson's AMS Device Manager or ProComSol's DevComDroid Android app, to parameterize, monitor and evaluate HART field devices via this open communication standard.

Want to know how HART-IP can benefit your company? Contact us today to talk to one of our experts.