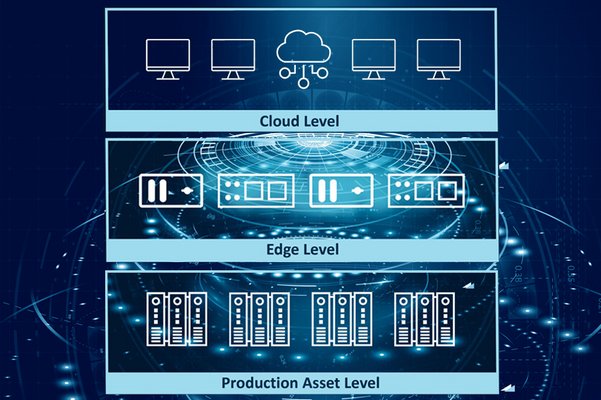

IIoT and Industrial Edge: From Concept to Implementation

What does Industrial Edge mean? What role does it play within an IIoT architecture? And how do cloud services from Amazon Web Services (AWS), Microsoft Azure, and open source container tools like Kubernetes complement this architecture and help companies improve their processes? Our blog answers these questions and shows three projects in different stages of realization.