Industry 4.0 Implementation for HART Devices

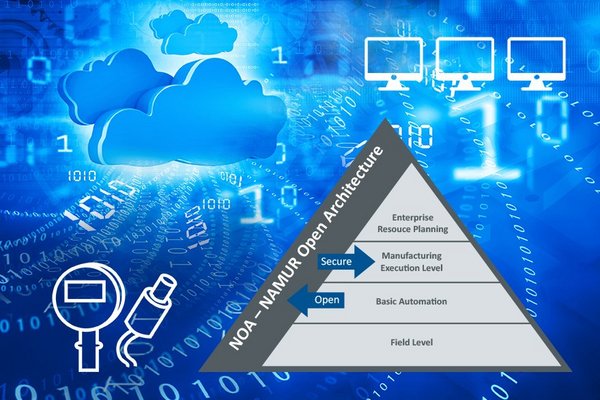

An essential feature of modern Industry 4.0 solutions is the networking of machines and plants. If a continuous digital data flow is guaranteed across all production levels, data from intelligent field devices can provide well-founded information on the plant status. In this way unplanned outages can be avoided, downtimes reduces and maintenance costs lowered. How does this work in the ideal case?