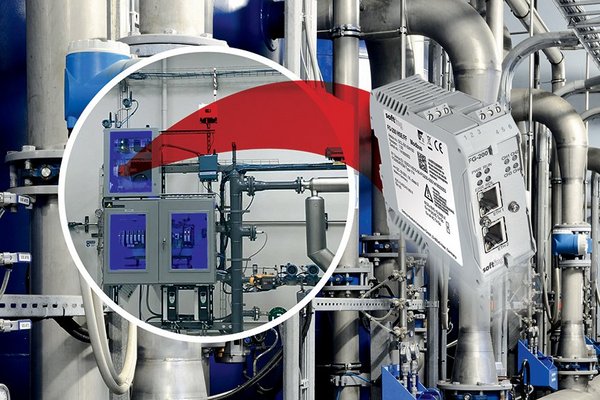

Industrial IoT Automation – Smart Data Integration With dataFEED Software Platform

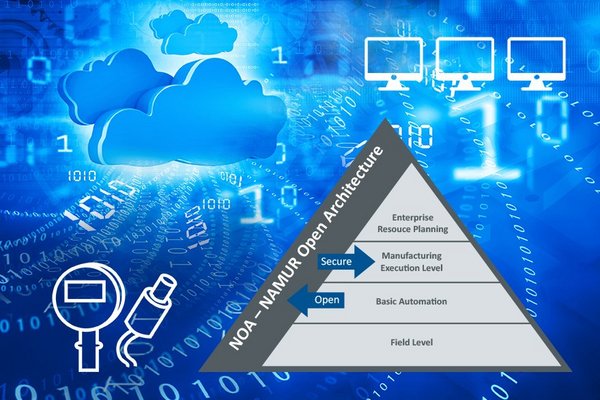

Data integration and IoT or Industrie 4.0 have been fueling the market for many years and are finally on the verge of a breakthrough and success, because it is now possible to integrate and successfully use the incredible range of technologies and the vast amount of sensors, data formats and conceivable usage scenarios. The same can be said for the volume of data currently produced. In the "Internet of Things" or Industrie 4.0, a seamless data exchange between Operational Technology (OT) and Information Technology (IT) is crucial for competitiveness and success. However, this is not the only decisive factor. Production processes, both in manufacturing and in the process industry, require continuous improvement in efficiency and performance - this can only be achieved in the future through innovative, reliable data integration.