A fast track to your field devices

Mobile modems for intelligent field device management

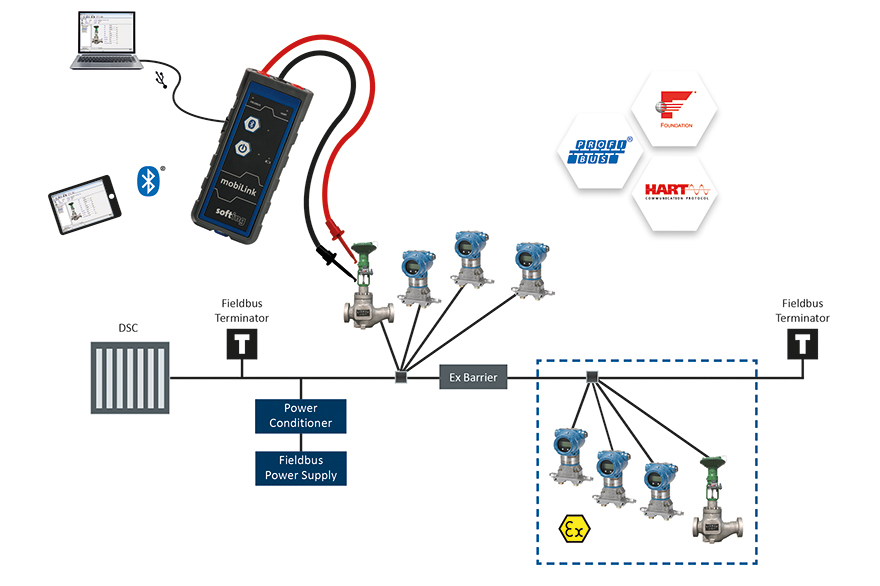

From a technician’s point of view, process automation can become a major administrative headache, with its virtually unlimited number of configurable parameters plus the various communications protocols and field device interfaces. A modern process architecture can easily consist of up to 1,000 field devices from multiple manufacturers, which gives the technician the Herculean task of ensuring efficient commissioning, cost-effective operation, and maintenance – as well as ad hoc fault detection and troubleshooting. With the compact family of mobiLink modems from Softing, commissioning, parameter setting, operating and maintaining these field devices has just got a whole lot easier.

Field devices in process automation: the status quo

Previously, efficient field device administration and maintenance had been virtually impossible, given all of their various technical models and variants. This is why several organizations decide to tackle this problem by developing specialized technologies for integration and data provisioning based on open architectures that were protocol- and manufacturer-neutral. Even so, a global “standard” could not be agreed and so three data transfer protocols still remain in active use on the market:

HART

Foundation Fieldbus

PROFIBUS PA (PA: process automation)

Another important consequence of this highly heterogeneous infrastructure becomes apparent when it comes to field device configuration, downstream data processing and the applicable interfaces – including interoperability and flexible integration. Consensus also proved to be impossible here, and the goal of a “universal” solution remains out of reach even today. As a result, users either need to deploy electronic device descriptions (EDDs), device drivers with an integrated user interface (field device tool/device type manager, FDT/DTM), or a combination of the two (field device integration, FDI) as an integration technology.

mobiLink – the first interface that does it all

So it’s no surprise that the above scenario has had device admins looking urgently for a cost-effective and above all user-friendly solution that could help to reduce the effort needed for field device commissioning, parameter setting, operation and maintenance.

mobiLink from Softing – a phone-sized device weighing just 300 g – is the first battery-powered tool to offer connectivity to intelligent field devices and online plant systems via one of the three industry-standard protocols (HART, FOUNDATION Fieldbus, and PROFIBUS PA) in a single device family. The mobiLink device provides the functionality of a HART master, a FOUNDATION Fieldbus host and a PROFIBUS PA master, which makes it straightforward for users to complete configuration, administration or troubleshooting tasks. Devices in this family also provide an interface for data provisioning and for integration into turnkey solutions, as well as connectivity conforming to the EDD, FDT/DTM and FDI standards.

How does mobiLink handle ‘three-way’ communications?

Inside a HART environment, mobiLink reads the primary process values from the connected HART devices via a 4-20 mA current loop, while also supplying power to the field devices via a powered HART loop. Communication over the Foundation Fieldbus and PROFIBUS PA protocols makes use of an identical physical layer. The electricity supply in this scenario is handled by a powered fieldbus segment. During connection handshaking, mobiLink checks fieldbus voltage and polarity. If these are not correct, no connection is then established.

Communication with a host computer or tablet is handled by the Bluetooth or USB interface. All popular FDT frame applications can be integrated such as FieldCare from Endress+Hauser, FieldMate for HART and PROFIBUS PA from Yokogawa, PACTware, LabVIEW and Field Device Manager from Honeywell. The optional DevCom (DD) App by ProComSol, a leading provider of HART communication solutions, makes it possible to easily configure field devices using a Windows, Android or iOS device. A dedicated driver for FF is used for deployment of the FieldMate field device management tool from Yokogawa. Thanks to IECEx and ATEX approval (ATmosphères EXplosibles), with Ex approval for Zone 1 and 2, mobiLink is also generally suitable for deployment in explosion hazard areas. This Ex rating – which mobiLink is the only device of its kind to have been issued with worldwide – is an important safety factor, offering reliable and safe testing for field devices used as part of process systems in potentially explosive atmospheres, for example.

mobiLink Power – wired for power

mobiLink Power extends the mobiLink family with a device offering the same performance characteristics as mobiLink, with support for the three HART, FOUNDATION Fieldbus, and PROFIBUS PA protocols. But unique to mobiLink Power is the option to supply power directly to field devices via USB from an external computer – which is plenty enough to operate the majority of field devices on the market. However, please note that mobiLink Power does not feature integrated Bluetooth and is not approved for Ex use. This makes it suitable for office and lab use, and especially for pre-configuration of devices before these are swapped out with devices in the field – or for training. The ideal solution for predictive and preventive maintenance, servicing and staff development work.

Two interesting technical articles have been published on mobiLink, which we would like to share with you. Click here for the articles from technical magazines Industrial Ethernet Book and AUTlook.

And here are the key features of mobiLink at a glance

Multi protocol operation

- HART-Master, Foundation Fieldbus Host and PROFIBUS PA Master

- HART loops for individual interaction with field devices

- Complete and compliant protocol implementations allow for interference-free operation

- Parameterization/configuration of field devices as well as diagnostics and health monitoring

Host communication via Bluetooth or USB

- Battery operation and Bluetooth interface

- USB interface for bench host operation

Support for FDT frame applications and engineering tools

- PACTware FDT Frame Application and HART Communication DTM

- Communication DTM for Foundation fieldbus and Profibus PA

- Foundation Fieldbus configuration tool

- Application program interface for integration into engineering systems

Certifications

- IECEx and EX approval for Zone 1 and 2, NEC500 Cl. Div.1

- Suitable for connection to intrinsically safe circuits

- Full touch protection according to IP54 (international protection codes)

mobiLink Power

- Power supply for field devices provided via the USB port of the computer

- No power conditioner for workbench applications required

- No Ex approval and no Bluetooth interface

We have compiled further information on the mobiLink family, such as technical articles and data sheets for you here.